Powder Small Mini Auger Feeder

Friday September-12 2025 15:12:01

Powder Small Mini Auger Feeder can convey materials prone to bridging and adhesion, such as titanium dioxide and milk powder, as well as hard, abrasive metal powders and quartz powder.

Due to its compact size, the Powder Small Mini Auger Feeder's lengths range from 300mm to 1500mm, with feeding capacities ranging from 5g/h to 500kg/h. Control accuracy varies depending on the drive method: stepper motors offer approximately ±2-3% accuracy, while servo drives or loss-in-weight systems can achieve ±0.5%-1%. The spiral structure is selected based on the material's characteristics. Shafted spirals are suitable for low-viscosity, high-flowability powders, while shaftless spirals are specifically designed for high-viscosity, agglomerated, or impure powders.

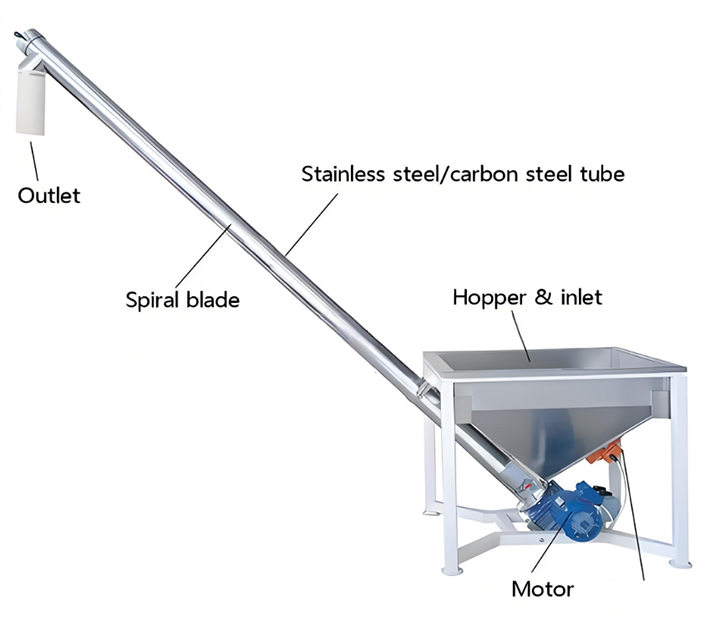

Powder Small Mini Auger Feeder Structure

The structure and function of the Powder Small Mini Auger Feeder are as follows: The miniature spiral feeder conveys powder via a motor-driven spiral shaft. The spiral feed hopper serves as a material storage and flow guide, ensuring smooth powder entry into the spiral and preventing bridging. Miniature dosing screw feeders achieve highly precise quantitative control of powder output by precisely controlling screw speed or motor stroke.

Powder Small Mini Auger Feeder Types

Powder Small Mini Auger Feeders are primarily categorized into the following four types, depending on whether the screw is horizontal, vertical, or flexible spring steel. They are suitable for powders with high viscosity, moisture, or clogging, and for small batch production needs.

Standard Horizontal Powder Small Mini Auger Feeder: The most common type features a horizontal screw shaft and a separate small hopper. This versatile design is suitable for most powder conveying applications, with a typical conveying capacity of 0.5-50 m³/h.

Vertical Powder Small Mini Auger Feeder: The vertical screw shaft is typically installed directly at the bottom outlet of a main silo (such as a bulk bag or large hopper). The vertical screw pushes and discharges the material upward, with a conveying capacity of 1-25 m³/h. This type is suitable for applications with limited space or when material needs to be directly retrieved and lifted from a large storage silo.

Flexible Spiral Powder Small Mini Auger Feeder: The spiral is made of flexible spring steel, and the tubing is typically soft plastic or rubber tubing. The device has a conveying capacity of 0.1-5 m³/h. Its compact design makes it easy to install, move, and clean. It is suitable for conveying non-abrasive, free-flowing, lightweight powders and is often used in laboratories, small-batch production, or when frequent material changes are required.

Shaftless Powder Small Mini Auger Feeder: This device has a continuous spiral strip without a central axis. This design effectively prevents tangling and clogging. It is ideal for conveying materials prone to tangling, adhesion, and bridging, such as sludge, sticky powders, and fibrous materials. Typical models have a conveying capacity of 0.3-30 m³/h.

Powder Small Mini Auger Feeder Specifications

| Model |

Spiral diameter (mm) |

Pitch (mm) |

Speed (r/min) |

Delivery capacity (m3/h) |

Motor power (kw) |

| 100 | 114 | 3 | 100 | 1 | 0.15-0.45 |

| 114 | 114 | 5-10 | 140 | 3 | 1.6 |

| 159 | 159 | 10 | 120 | 10 | 1.5 |

| 160 | 160 | 35 | 120 | 8 | 2.8 |

What are the benefits of a Powder Small Mini Auger Feeder?

The Powder Small Mini Auger Feeder is compact and can be flexibly placed in factories with limited space. It's suitable for conveying materials such as talc and activated carbon in the chemical industry, flour, coffee powder, and seasoning powder in the food industry, medicinal powders in the pharmaceutical industry, and cement and putty powder in the building materials industry. Adjusting the spiral blade's pitch, speed, and other settings ensures stable conveying. Its enclosed structure prevents powder from flying and getting wet.

The Powder Small Mini Auger Feeder is a key device for conveying powder materials. It can be customized to meet your specific length and material capacity requirements. For example, wheels can be installed underneath for easy mobility, and a stand can be installed to ensure stability and enhance powder conveying. Consider our factory, which has been manufacturing equipment for over a decade. Our professional design engineers can recommend custom models based on your specific requirements.